This post will explore and explain what you can expect from a cobot (collaborative robot) and everything you need to know about palletizing with Universal Robots.

Cobots may become your future colleagues, and by the end of this article, you might find that a palletizing solution from Universal Robots could be just that – your next colleague.

This article will specifically focus on palletizing with collaborative robots from Universal Robots. For more general information about cobot palletizing, read this article:

Palletizing with Cobots – Everything you need to know

Palletizing with Universal Robots

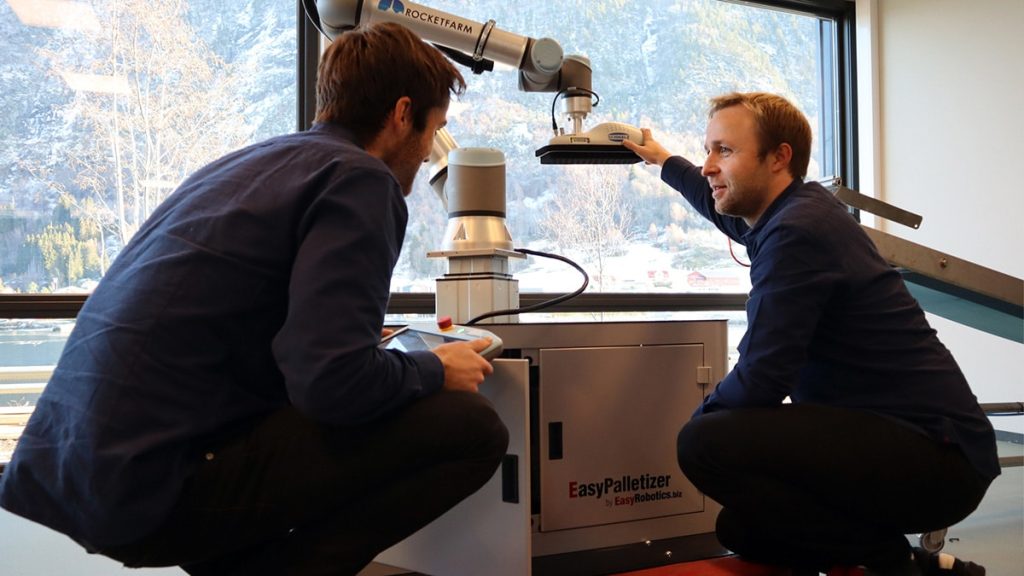

Universal Robots is a Danish company based in the robotic cluster of Odense and was the company that introduced cobots to the market. They have since then developed into one of the largest manufacturers of cobots. With over 100,000 cobots sold worldwide (as of 2025), thousands of companies share their vision of creating a world where people work with robots, not like robots.

Cobots from all brands can do palletizing, but in this article, we will focus specifically on Universal Robots. The reason for this is that UR produces cobots that are highly suitable for palletizing tasks, and as palletizing is our area of expertise.

Cobot Palletizing

In a collaborative workforce, robots work alongside humans rather than replacing them. This is how cobots work. Applying them in the workforce will capture the best qualities of humans and robots.

A cobot palletizing solution places boxes from the assembly line onto a pallet. It does so with accuracy and efficiency. With a cobot palletizer in your workforce, you will work alongside an easy-to-use, flexible solution. A solution suitable for many of your various palletizing needs.

The complete solution consists of three main components. The cobot itself, the software, and the hardware components, such as a gripper, sensor, base frame, or lifting column. As you can imagine, the opportunity to customize is huge. This also enables the solution to fit into a wide range of different palletizing projects.

Pally Software in Universal Robots

Our software, Pally, is the market-leading palletizing software for Universal Robots. Pally enables you to achieve a higher case throughput per minute and enhance safety. It is also very easy to use and install, which adds direct value to our customers.

Learn more about Pally Palletizing Solutions

Benefits of a Universal Robots Palletizing Solution

- Solve manufacturing problems: You could be fearing negative consequences from robots taking over jobs. However, in reality, these solutions can improve your job by reducing workplace-related injuries, which are often associated with heavy lifting and repetitive tasks. Instead of doing this on your own, the palletizing cobots from Universal Robots can be of service. Furthermore, aiding the workforce in the palletizing process.

- Struggling with finding labor? If so, you are not alone, as this is becoming a growing concern. A cobot can solve your issues in a cost-effective and safe manner. A cobot palletizing solution delivers the same precision every hour of the day and every day of the week.

- Return on investment: You may think that an investment in a cobot is expensive and only applicable to large firms. However, many businesses show a positive return on investment within the first year. A UR cobot palletizing solution has, at the very least, a lifespan of approximately 35,000 hours. After roughly 3000 hours, you can expect a positive return on investment. And Pally can prolong the lifespan of the cobot, which increases the value of the investment.

- Easy and flexible: Other benefits include easy programming. This allows you to provide desired work instructions without needing to be a robot expert. The setup time is short, and they are easy to redeploy if you want to move them to a different process. Using Pally in this regard makes these changes a lot simpler. For learning how to deploy and reprogram UR robots, it is recommended to spend time in the UR Academy and have a UR Super User in the company.

- Reliability: There are costs associated with finding substitutes, training them, and keeping them. These are not very tangible costs to asses, even tho they are very relevant to your business. But the UR cobot is a loyal worker. It is best suited for repetitive and heavy tasks that none of your employees particularly enjoy. Once the cobot is set up, it will continue to perform every day.

“They told us that customers buy robots thinking to become more productive, but then discover that the biggest change is greater quality and reliability in their operations.”

Statement from a manufacturer of welding robots

- Shows ambition: By investing in automation, you demonstrate to the world that you have invested in your production. However, it is also worth noting that you have invested in keeping your production in-house, which should have a positive correlation with your hiring processes. Now, applicants can see that you have committed and are on a journey of automation. This is more attractive than standing beside a century-old machine.

Cobots Suited for Palletizing

Universal Robots offers several types of cobots that are well-suited for palletizing applications. Continue reading if you’re curious about which one suits your business.

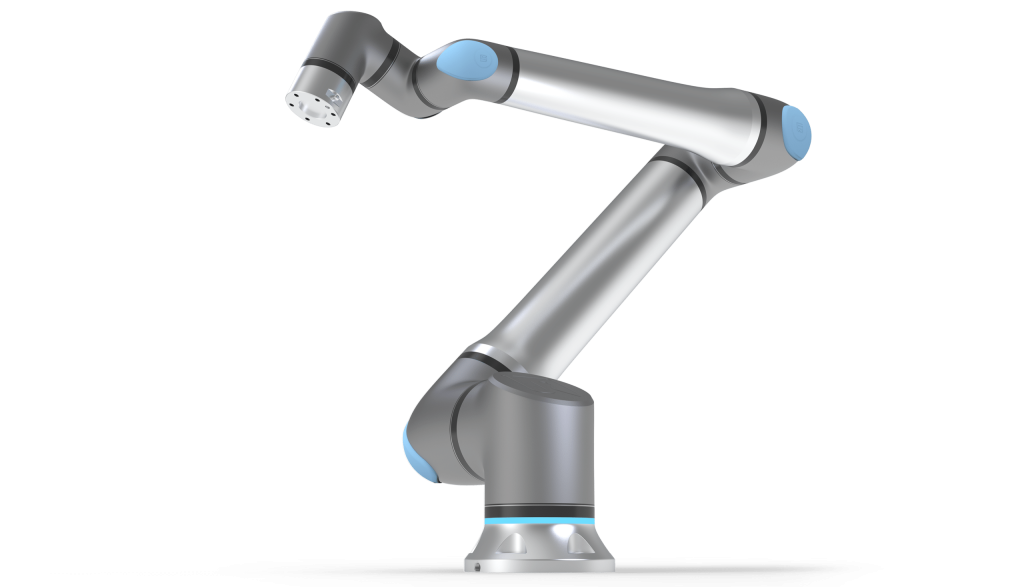

UR10e

The UR10e is the best-selling cobot from Universal Robots. This cobot lifts up to 12.5 kg, providing high performance and efficiency. It has a reach of 1300 mm, and the payload is sufficient to allow multipick. Rocketfarm has an installation that lifts up to 50 cases per minute (CPM), but this is a special case. In most use cases, 30 CPM is the fastest. (The high CPM attained through multi-pick is only possible with our Pally software). Additionally, the UR10e has a footprint of only Ø 190 mm.

All in all, there is a reason why the UR10e is a best-seller. It allows you to boost productivity and increase product quality. Also, it unties your workforce from repetitive and heavy tasks. It’s collaborative and safe, and the UR10e offers one of the fastest payback times in the industry. Furthermore, it can also do various tasks due to its combination of payload and reach. This makes the UR10e excellent for palletizing.

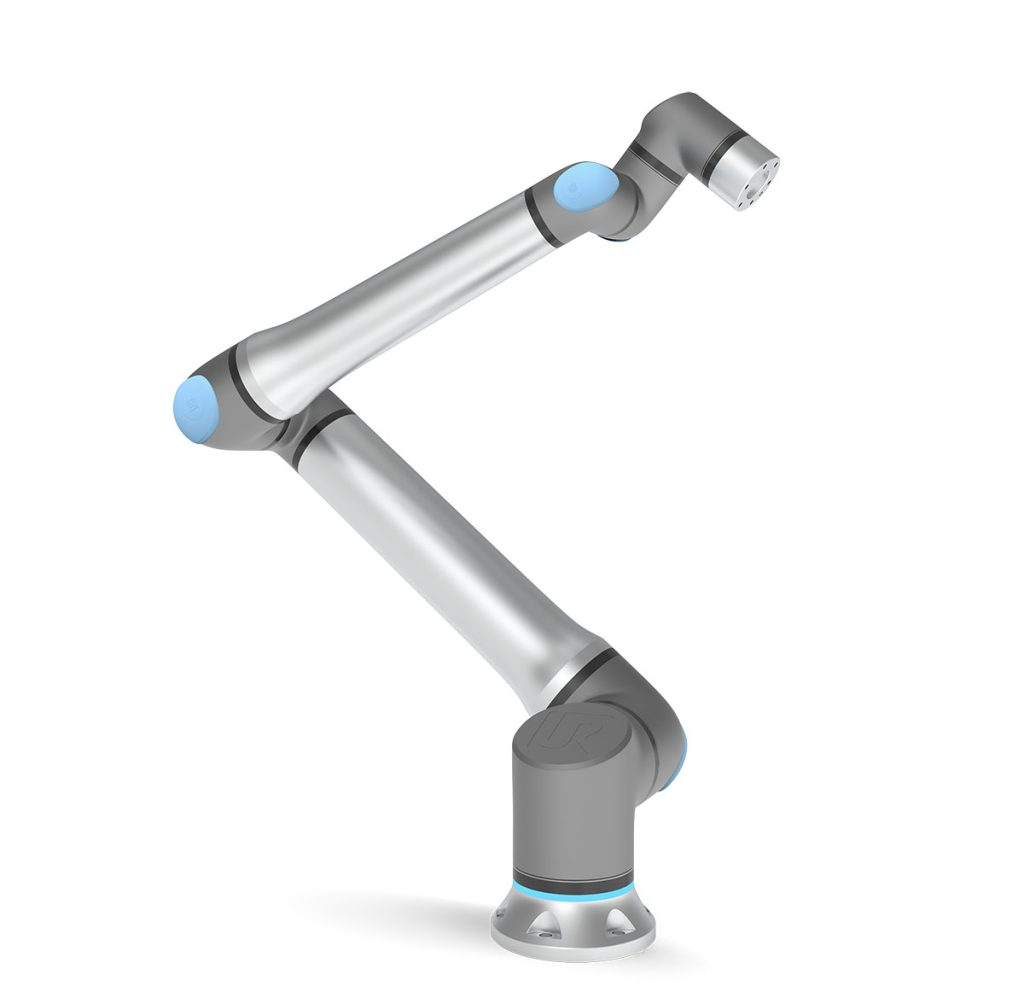

UR20

The UR20 is Universal Robots’ largest collaborative robot (cobot). In our opinion, it is the perfect cobot for palletizing.

UR states it is their first cobot in the next generation of industrial cobots. It has a high payload of 25kg and a long reach of 1750mm, making it highly suitable for palletizing projects. Its footprint is still small (ø 245mm) and can be moved up to 65% faster than other UR cobots.

Learn everything about palletizing with UR20 in our in-depth analysis.

UR30

The UR30 is Universal Robots’ latest addition to its next-generation industrial cobots. With a payload capacity of 35 kg and a compact reach of 1300 mm, the UR30 is ideal for high-payload tasks in tight spaces, including palletizing applications where strength and precision are crucial.

Despite its powerful performance, the UR30 maintains a small footprint (ø 245mm) and offers the same fast motion and control capabilities introduced with the UR20, making it able to tend larger machines, palletize heavy products, and effectively support high torque screw driving.

Which one to Choose?

The differences between cobots are less varied than those of other types of industrial robots. However, there are some key differences to consider when making a choice:

- Payload (UR10e: 12,5 kg vs UR20: 25 kg vs UR30: 35 kg)

- Reach (UR10e: 1300 mm vs UR20: 1750 mm vs UR30: 1300 mm) (This is very relevant for palletizing)

- Footprint (UR10e: ø 190 mm vs UR20: ø 245 mm vs UR30: ø 245 mm)

- Weight (UR10e: 33,5 kg vs UR20: 64 kg vs UR30: 63.5 kg)

Let MyRobot.cloud Fast Track Help

We recommend that you don’t make the choice on your own. Let the Fast Track help you find the available cobot palletizing solution in your region. Visit our cobot palletizing search engine and enter your product specifications to receive a simulation and project report within one hour.

The simulation and project report will serve as upfront verification, ensuring that your specific palletizing project will function properly when installed at your facility.

Choose a Pally Palletizing Solution

The core of a Pally palletizing solution is our software, Pally. It is the leading palletizing software for Universal Robots. We are a UR+ approved software developer and are recommended for palletizing by Universal Robots.

Easy to Install and Easy to Use

There are numerous benefits associated with using the Pally software in a palletizing solution. Some of them can be quick and easy to install and have a user-friendly interface. This makes it flexible in the sense that it is adaptable to changes in production. And making these changes requires no downtime. Pally also includes smart features that increase performance and its lifespan.

3 Steps from Pattern to Robot

Designing and changing patterns has never been easier. In the Robot Management Platform MyRobot.cloud, you design your pallet. You can include shim paper, interlocking layers, or use the recommended patterns. After building your pallet, download the .JSON file and upload it to your robot. Then, it will palletize with the new pattern without impacting the production line.

Optimized for Longevity and Performance

With optimized path planning and multi-pick capabilities, it is possible to palletize at a rate of up to 60 CPM. But this depends on the pattern, product, and payload. Together with Universal Robots, Pally can also palletize higher pallets by using lifting columns. This makes every pallet count.

Learn more about Pally Palletizing Solution

Palletizing with a Cobot from Universal Robots

Palletizing is an obvious task for automation. It is dirty, dull, and dangerous. By automating your palletizing, you can free your employees to take on more valuable assignments and achieve a positive return on investment quickly. If your product payload and production speed are within the range of possibility with UR cobots, they are a really good option when choosing your palletizing solution.

If you would like to learn more about palletizing with Universal Robots, please don’t hesitate to contact us. We’re happy to help with any questions you might have!

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.