dPally URCap

Your advanced Depalletizing Software for Seamless Automation

Looking for an efficient and flexible depalletizing solution? Rocketfarm’s dPally URCap delivers smooth, safe, and fast operations.

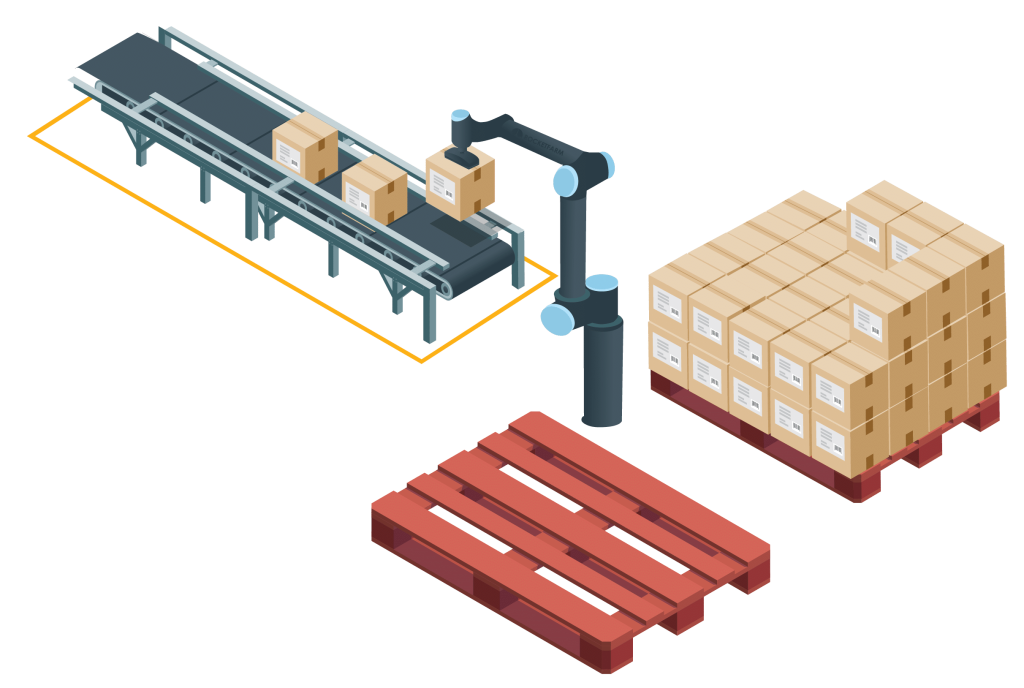

Why Depalletizing?

Unlike palletizing, depalletizing involves variable conditions like box placement and pallet types and is a more challenging task overall. One important reason is that picking boxes from a full pallet is less accurate than picking them from a conveyor belt. Learn how depalletizing differs from palletizing here.

dPally addresses these challenges with optimized path planning, controlled pick-up, and adaptable hardware integration – ensuring accuracy and efficiency every time.

Get To Know dPally

Depalletizing Made Easy

The dPally URCap is developed based on our well-established Pally Software, the fastest collaborative palletizing software on the market.

dPally is designed to handle complex tasks efficiently. It requires no vision system and is a cost-effective solution that supports custom-built and standard hardware. It is also the most advanced depalletizing software for Universal Robots, as you can depalletize from two pallets onto two conveyor belts.

Up to 30 CPM

Compatible with UR30, UR20, UR16e & UR10e (also supports CB-series)

No-code installation

What Makes dPally Stand Out

Create Success

Don’t miss the opportunity to add the dPally URCap to your solution portfolio.

With its competitive pricing, easy integration, and robust capabilities, dPally helps your customers achieve greater efficiency, faster ROI, and a seamless transition to automated depalletizing.

*$8.700

Get In Touch

If you want to expand your automation offerings, dPally is designed to help your business thrive. Contact us to schedule a demo and learn more.

Brigt

Channels Executive

+47 969 14 006 (08:00 – 16:00 CET)

brigt.roysum@rocketfarm.no