UR20 – cobot for palletizing

Universal Robots just released its newest family member of the UR cobot family, the UR20. Undoubtedly, UR must have had palletizing in mind when they designed the UR20.

Having worked with UR for palletizing applications for 7 years, we have dug into the details of what we know and what we don’t know, and simply assume the UR20 will contribute within the palletizing space.

Also explaining why bigger is safer for many palletizing use cases.

Palletizing is an application where the benefits of automation is huge. With a cobot palletizing solution it’s very available for SME’s.

Learn more about why we believe UR20 is a good choice for palletizing automation. We will go into a deep analyzes of why UR20 will contribute to the market of palletizing robots and it’s limitation.

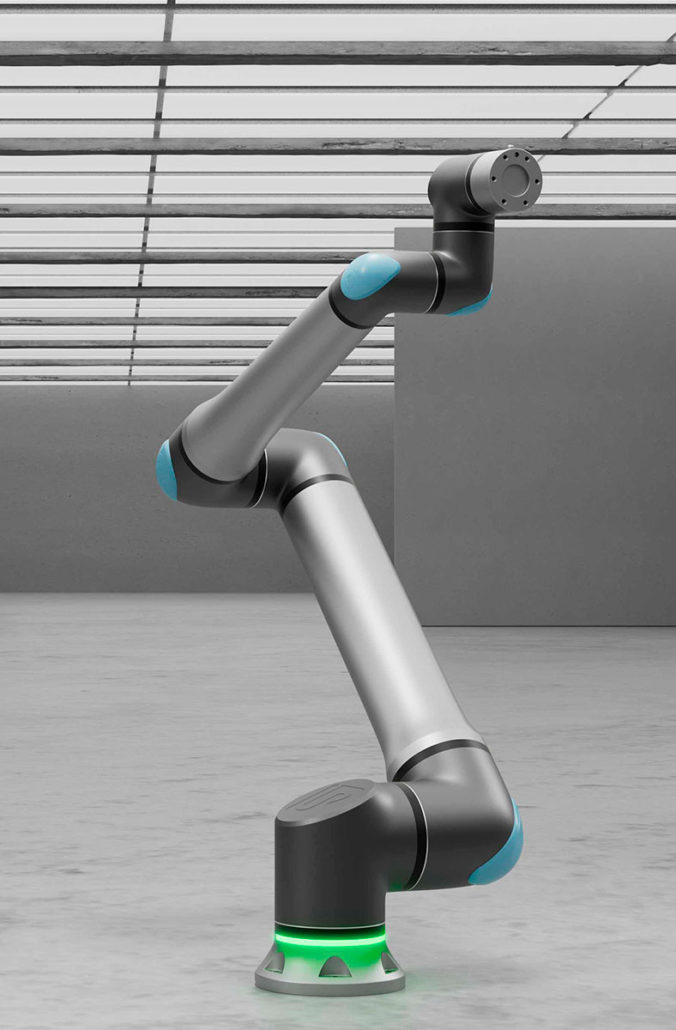

What is the UR20 cobot?

The UR20 is the newest addition to the robot quiver from danish Universal Robots (based in the robotic hub of Odense). It’s a larger collaborative robot with a payload of 20kg (in the full range of motion) and a reach of 1750 mm.

Learn everything you need to know about UR20 and it’s specification in this article

In this article we will focus on the possibilities for UR20 within the application of palletizing. As this is our expertise. We have worked with UR Cobot Palletizing since 2015 and our Pally software is the market leading software for cobot palletizing.

In many palletizing situations bigger is safer, and the new possibilities with UR20 is a welcome addition to the market of collaborative palletizers.

Halvor Gregusson

CIO at Rocketfarm

Short introduction to cobot palletizing

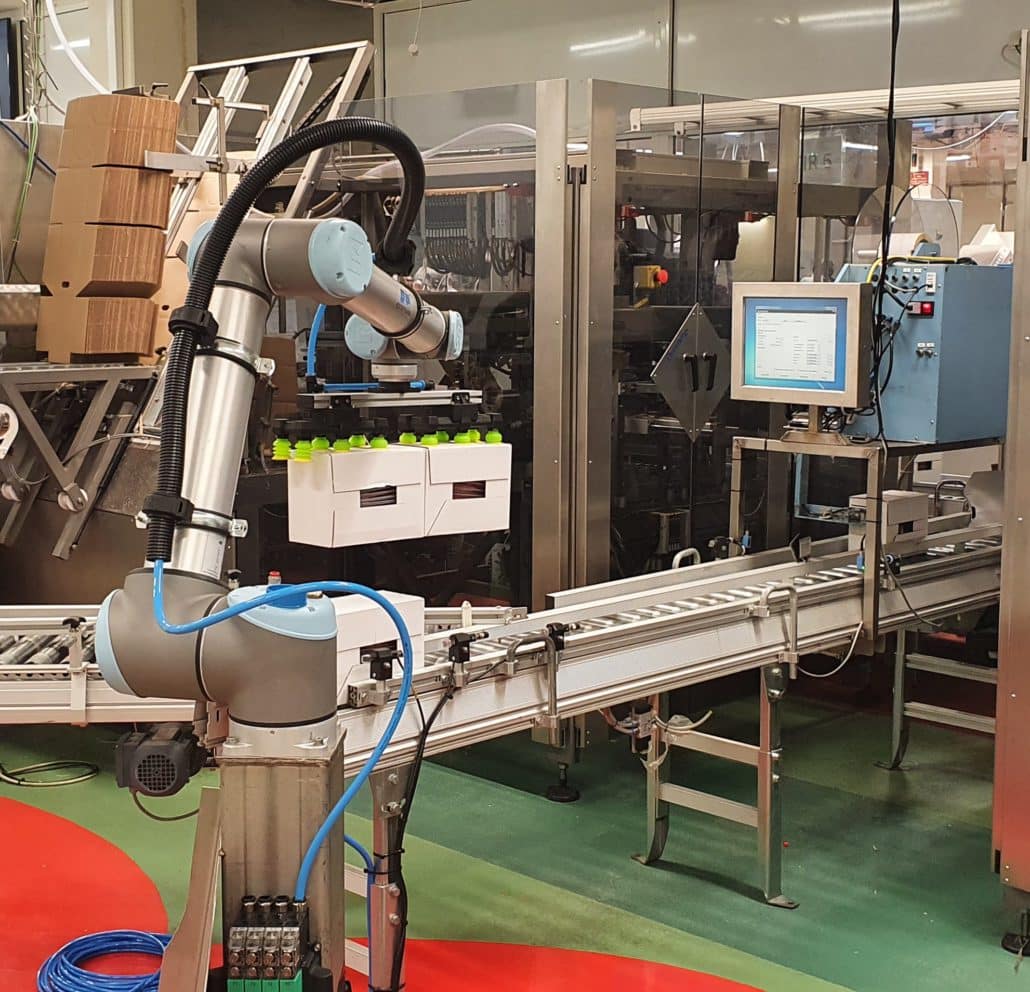

In short, palletizing is the process of stacking products from a conveyor belt to a pallet. Depending on product specifications and production speed, this task is performed manually, with palletizing machines or palletizing robots. Additional specifications like height, width and stacking pattern of a complete pallet are also important to analyze before choosing the right palletizing solution for a production line.

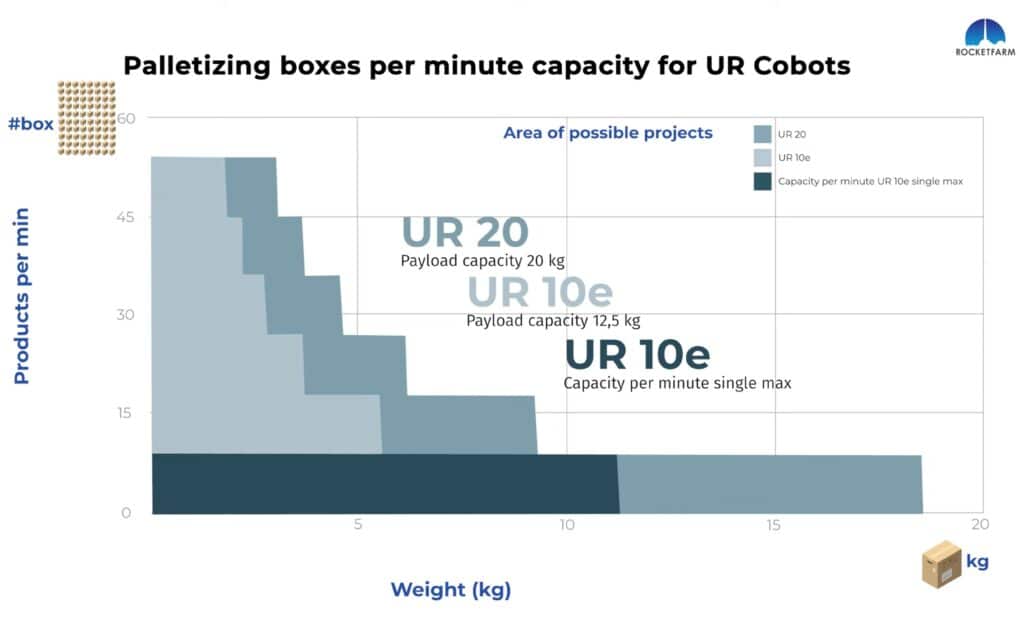

Collaborative robots, or cobots, are usually used where the production speed is below 30 products/min and where product weight is within the scope of payload capacity of the cobot (with UR20, anything below 20 kg).

UR20 price

Starting with what we still don’t know, the price. This seems to still be unsettled within UR too beyond the stated “it will not be the cheapest in the market”.

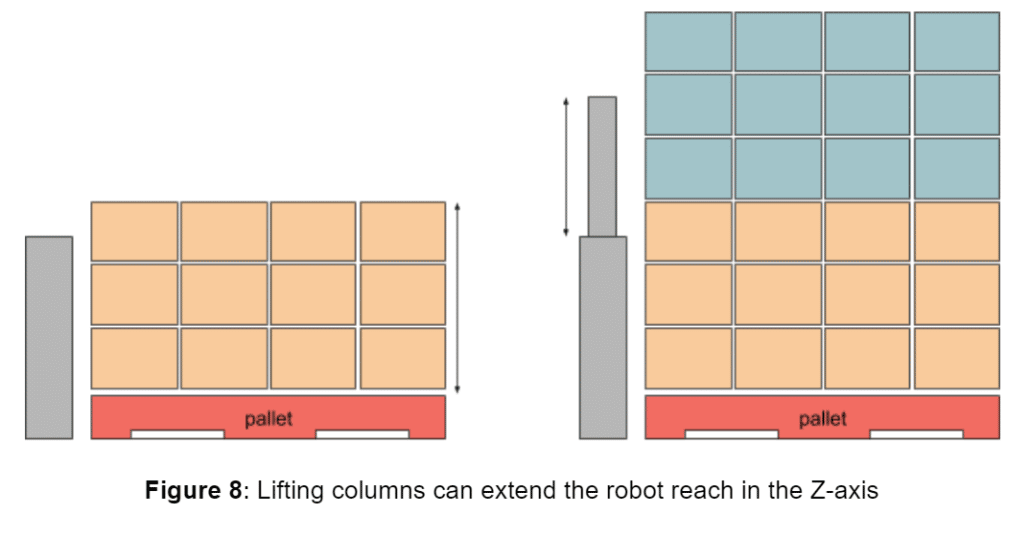

However, for palletizing as for many other applications, the cobot is only one of several components. With UR20s extended reach, you will find that in many scenarios, the UR20 will remove the need for a 7th axis (lift), which are priced between 2-4k EUR, which in turn may catch up some (hopefully all) of the expected price difference between the UR10 and the UR20.

UR20 for palletizing

As mentioned in the beginning we believe UR20 is a very suited robot for palletizing. And it’s not just us. Universal Robots have also highlighted that possibilities with UR20 in palletizing.

There’s several reasons why UR20 seems designed for palletizing. Below we will dig into the details of the cobot to analyze everything that we know and what we don’t know about UR20. Always in relation to palletizing as that’s what we know a lot about.

Extended payload and reach

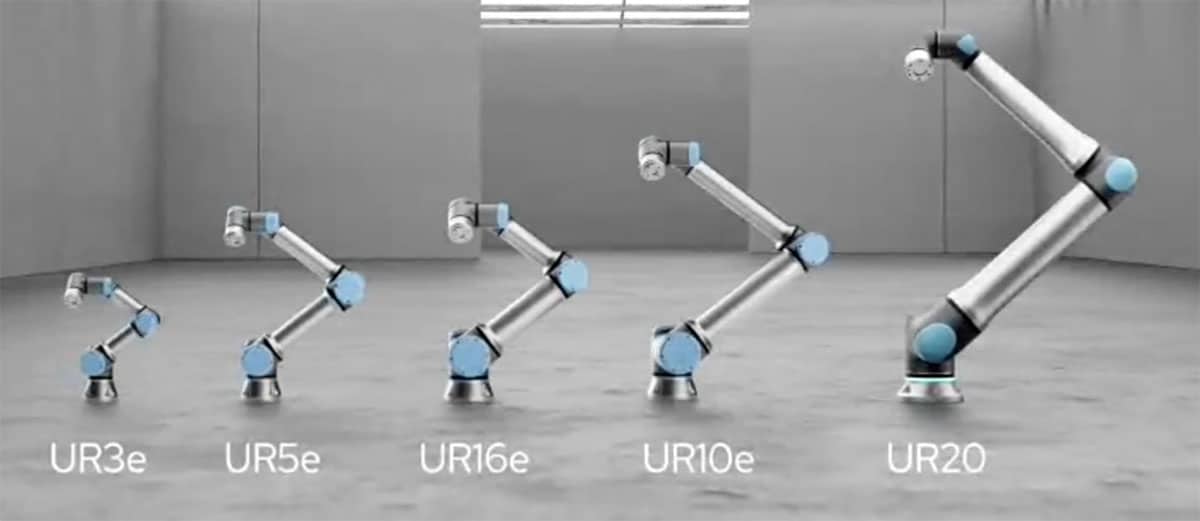

Stating the obvious for anyone familiar with the naming convention of Universal Robots. UR20 = 20kg payload. With a payload capacity of up to 20kg it “only” exceeds the UR16e with 4kg extra payload capacity, but for cobot palletizing applications there’s another feature that makes it far superior to its predecessor. It’s bigger! A lot bigger!

With a reach of 1750mm, it outperforms both the UR16e and the UR10e by a landslide. It is the combination of payload and reach that turns the UR20 into a palletizing cobot by design.

UR20 vs. UR16e

Let’s compare the UR20 to the UR16e as an example. Although heavily underestimated by the UR community as simply “too short” to reach those far corners of a pallet, it does have it’s natural limitations to stack those taller and wider pallets which in particular is true for US compared to the EU standards.

Even with extensive use of a separate 7th axis (lift), our assumption is that the UR16e is simply perceived as “too short” by the community, and as a result, the UR16e has never really been even considered palletizing.

UR20 vs. UR10e

The UR10e on the other hand is in many scenarios a great palletizing cobot. For a number of scenarios, especially when working on EU1 pallets, the reach is long enough to manage without a 7th axis, (something that can easily be verified through Digital Twin Simulations).

Using a 7th axis will for practically all palletizing scenario provide the necessary reach given you use a palletizing software capable of optimizing reach due to gripper orientation at grab and release.

But, in contrast to what the naming may indicate, its payload capacity is “only” 12,5kg. There is a huge gap from 12,5kg to 20kg when it comes to palletizing.

Despite what you may think, there are several reasons why this payload gap from existing UR cobots to UR20 represents so much more than the few kg difference.

The human pain point

First, let’s point out a key selling for any robots. There are several tasks that humans simply shouldn’t do. Picking and placing boxes of 10kg from a conveyor belt to a pallet is already in the pain point area of what will wear a worker out. Moving into the 10kg to 20kg area of payloads, we are in the zone of heavy human labor. Being a palletizing cobot for this interval, the UR20 is solving more than swapping people with cobots. It will do work in an interval considered much more painful to humans.

Bigger is safer

From an “industrial robot” point of view, more payload and reach is usually linked to “more power” or “stronger”, with a natural line of thought that it also becomes more dangerous if it hits a person or you get trapped by it. However, UR20 is still a cobot. This does not mean it can’t hurt you if it hits you, but it will stop IF it hits you. So what makes this different from a UR10e you wonder?

Same polyscope version

First, what is not different from a UR10e, and keep in mind we are talking about palletizing applications. What we do know, is that UR20 will be running on the same Polyscope 5 as the UR10e. This means that the features from UR10 are also available for UR20. With this feature set, you can easily configure safety planes which the robot will, certifiably, not exceed.

An example of what you can do: Reduce the operation area to be equal to the UR10e. By using this feature the extra reach does not represent a bigger area of operation for the cobot.

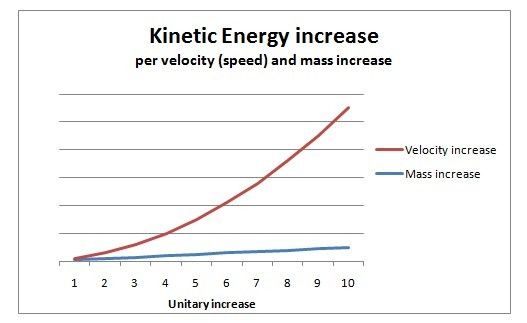

Collision energy is the key

Secondly, what is different from a UR10e, and still keep in mind we are talking about palletizing. Due to the fact that the cobot stops if it hits you, the danger of a cobot is much more linked to the collision energy of the system than the force it can push a person towards a barrier.

Hence the collision energy of an impact is key to determine the hazard level of the application. And for the purpose of simplifying the “ISO 15066 Robots and robotic devices — Collaborative robots” , the collision energy of the system follows the equation of:

E=1/2mv^2.

Speed is everything

It may not be obvious at first glance, but what it really tells you, is that the speed of the system is for this scenario almost everything that counts.

And here’s the catch: Extra payload can be transferred into slower speed, thus far less collision energy.

Let’s do the math

Let’ts investigate it with an example. Let’s say you require a 6kg product to be palletized at a required 9 products/minute pace onto a pallet (if you only want the result, not the explanation, simply skip the next two paragraphs):

For this equation, the m refers to the complete mass of the system. This includes the weight of the cobot. (For simplicity, we use the entire weight of the UR10e, 35kg and UR20, 65kg).

Palletizing the scenario with UR10e

To do this with a UR10e, you would need to achieve a max speed of the system of at least 1,5m/s. Due to the payload limitations, and given the fact that at least 1kg of the 12,5kg capacity is needed for the gripper, this only leaves 11kg payload capacity, hence with 6 kg, the cobot can only grab 1 product per cycle.

This gives the following equation E=½ (6kg + 1kg + 35kg)*1,5m/s^2 = 47,25J.

Palletizing the scenario with UR20

Using the same requirements on a UR20, you are able to pick 3 products for each robot cycle, meaning you would only need to move at a maximum speed of 0,5m/s. Let’s say we also need to add 1kg extra on the gripper to multi-pick several products, we are still within the 20kg limit.

In this scenario, the equation looks like this. E=½ (18kg + 2kg +65kg)*0,5m/s^2 = 10,63J

Comparing the two scenarios

Comparing the two cobots, solving this scenario with the UR10e, we have a potential system energy of 47,25J. To give you an idea, this is equivalent to the energy of a baseball pitch of an “average 12 years old league pitcher” in the US. Or said differently, if you have a 12 year old son, pitching for the local baseball team in the US, and he pitches averagely fast. If you stood next to him and he accidentally hit you with his average pitch, that represents the same collision energy of the cobot in this scenario.

The same requirements solved with a UR20, only adds up to 10,63J. Almost a fifth of the energy! The average pitcher scale in the US does not go below the league of 8 year olds, but for 8 year olds, the average pitching energy is 21J, so lets simply say this scenario would correspond to a 6 year old pitching at you.

To put this really simply, if a 12 year old pitching hit you in the head, that would probably not be lethal, but you may require hospitalization. If a 6 year old pitched you in the head, it could definitely hurt, but you should be able to walk on.

Other factors

Now there are several other factors that come into play as well. Such as sharp edges, material you are palletizing etc, but the point here is to compare the different cobots. Also, the UR20 is heavier than the UR10e, so in theory if the cobot were to fall over you, it would be worse than a UR10, but we work under the assumption that it is properly rigged and installed.

Safety depends on the scenario

The morale is anyhow simple.

Safety depends on the given scenario, and the right question is not “how fast can the cobot move?”, but “how slow can the cobot move, but still make the speed requirements?”. Within Polyscope, you can apply different certified safety settings which correspond to the minimum speed needed for an application. In other words, guarantee that the cobot will never exceed a certain speed level.

Also worth noting is that “reducing the energy” of the robot system is listed above “safeguarding the robot” in the hierarchy of risk reducing measures (RIA TR R15.306-2016)

Safety depends on the scenario. Most often the right questions is not “how fast can the cobot move“, but “how slow can the cobot move and still make the speed requirements“.

Halvor Gregusson

CIO at Rocketfarm

Compatibility with other systems or components

We do not know if Universal Robots has hidden some new “gems” for us in the UR20, but we do know it will run with the familiar Polyscope 5 interface and that existing URCaps (URCap’s) will work on the UR20 as for the UR10e. But no news can also be good news. It means that URs comprehensive list of supported components through their UR+ ecosystem will also be available for the UR20.

An important detail though, to be able to deal with heavier payloads, UR has increased the size of the tool flange (connection point for grippers/tools etc). So there will be a need for an adapter if you have to work with tools made for any of the older robots (UR3e, UR5e, UR10e or UR16e).

Keep reading or download our free UR20 Ebook to learn more

Wear and tear

Little is currently known about the hardware components used in the UR20, except Universal robots has stated they have redesigned this robot from scratch, removing 50% of the parts to ensure robustness.

Assuming though, that they will still be using the Harmonic Drive gears, these gears have an expected lifespan of 30 000 hours of operation in the previous UR cobots. That again, follows from an expected use level of the robot which can be said to be with a “rough” use. Treat the cobot nicely, and it will behave nicely in return. And although having suffered a bit with their CB1 and CB2 series with respect to some quality issues, the UR cobots has been high quality since their CB3 serie release.

Laws of physics will apply

What to expect from the UR20 is unknown, but we do know the laws of physics. Just like low speed reduces energy levels in potential collisions, low acceleration reduces the tear and wears level of “any” mechanical joints with friction, which is exactly how a robot is designed.

Smart software improves lifetime value

Hence reducing the max robot speed, reduces the need for max acceleration which reduces the tear and wear of the cobot. With the higher payload capacity, you can more often pick more products per pick, hence you can reduce overall speed, acceleration and tear of the cobot.

Hence reducing the max speed, reduce the need for max acceleration, reduce the tear and wear of the cobot.

Removal of the 7th axis (lift)

The UR20 has an extended reach which should make it capable of palletizing without the need of a 7th axis. While less moving parts is generally a good thing and can contribute to a lower overall cost of the system, it does not necessarily mean lower complexity in the solution.

The positives

On the positive side, removing the need for a 7th axis also removes a potential risk for potential pinch points arising from the movement of the lift rather than the robot. While the cobot has certified mechanisms for stopping when hitting something, this functionality may not be true for all lifts. If you plan on designing a palletizer for yourself, make sure the lift has certified functionality for stopping if the “protective stop” signal in the cobot is triggered.

From an engineering perspective

From an engineering perspective, with a 7th axis you always had the option of moving the cobot to a more favorable position in order to either grab from the conveyor belt or release a product on the pallet. With a fixed position, this “luxury” is not present, and the path planning of the cobot needs to take this into account, adding complexity to the path planning and increasing the probability of collisions in the palletizing process.

More complex path planning

An example of this for the UR20 compared to the UR10e, is that you will need to take into account the extra length between the shoulder joint and elbow joint of the cobot, where the elbow is more likely to collide with a fully stacked pallet on the left side, while palletizing on the right, and vice versa. Either you will need for more optimized path planning or you will need to move the pallets further apart, increasing the overall footprint of the solution and reducing the max palletizing height of the system.

Programming

As mentioned, UR20 will be available with Polyscope 5 with support for existing URCaps. Whether you are considering purchasing a cobot palletizer or designing one based on the UR20, there are a few things to be aware of compared to a UR10e.

What to know before programming

First things first. For various reasons, think twice, and twice again, before even considering “the old way” yourself, programming line by line, each product placement of the pallet. Universal Robots has a free template script for palletizing which at least is a far better option to experiment with, however we strongly recommend to look into more specialized, “no code software” for palletizing like Pally for a number of reasons.

More advanced choices with less complexity

As mentioned above, the right question is not “how fast can the robot palletize”, the right question is “how slow can the cobot move and still meet the requirements?”. Choosing a software enabling the ability to switch between multi picking of boxes and single picking boxes based on pallet layout is not only a potentially faster option, it is also the safer option.

Though this certified safety level step also applies to the UR10e, the UR20 capability to pick multiple products more often, means it has more significance for the UR20.

Setting the certified safety level in the cobot to correspond with the pace at which the palletizing software/program can deal with the production speed is probably the most important, easiest and cheapest safety measure you can do.

Halvor Gregusson

CIO at Rocketfarm

Ability to easily do post installation changes

Secondly, with the UR20, the cobot has the ability to palletize a greater variety of products, meaning more frequent change overs between products, and more frequent post installation changes. In our experience manufacturers will find themselves quite annoyed with solutions where their own ability to add new products or add new pallet sizes requires an extensive knowledge of programming skills. Often meeting problems as “the one who knows it doesn’t work here anymore”.

Reach issues will remain complex

Third, the extra reach of the UR20 is definitely a huge advantage, but the mentioned added complexity that comes if you want to remove the 7th axis can for many scenarios make it more difficult to reach the far corners of a tall pallet and avoid collisions when palletizing close to the cobot.

Palletizing software is the key to a reliable outcome

Bluntly stated, the UR cobots have an easy interface to program simple pick and place applications. Palletizing on the other hand is actually a far more complex process. Don’t underestimate this. You will soon find yourself spending far more money than what you saved by choosing DIY, free software or so-called “turn key solutions” with a stronger emphasis on the hardware choices than the software implementation.

Choose a palletizing solution with a designated software. It pays out in the end. Choosing a palletizing solution without software is like purchasing a brand new laptop, realizing it runs on MS-DOS.

Mobility

If we were to state a weak point for the UR20 compared to the UR10, mobility is definitely it. While the UR10 with its 35kg frequently has been added to solutions which are easy to move between production lines, the UR20 is far more “clumsy”, and we expect the UR20 to be planned for more fixed installations. We don’t expect to see many UR20s driving around on MIRs or other automated vehicles.

That being said, it is our experience that while mobility is usually a good selling argument, most end customers who like the cobot rather start planning a second cobot than moving around the one they have.

When will UR20 be publicly available?

For the first time, a UR cobot will not be possible to purchase immediately after release. If this is driven by the need to convey a message to the market due to the fact that other cobot brands like Fanuc, Yaskawa and Doosan already have cobots in the same payload range, or if Universal Robots has realized that both customers and 3rd party network of integrators need time to plan and budget for the new cobot is not known.

In general Universal Robots has “opened up” more over the years and with their new CEO, Kim Povlsen, this trend seems to continue.

We expect the cobot to be available somewhere after Q1 2023, but the exact date is still unknown.

When can I start planning for it? Simulate it first!

The fact that the robot is not available in 2022 does not mean you have to sit around and wait. The digital files such as 3D models and control software will make it possible to plan, program and test the cobot in the digital world as soon as the necessary assets are available.

Whether you are a manufacturer looking for a cobot palletizer, or you are about to design your own standardized palletizing solution for the market, we strongly recommend that you look at what options are available to do good simulations of a real life scenario. Over the last two years, Rocketfarm has done close to 700 Digital Twin Simulations for feasibility and sales purposes for both end customers, distributors and system integrators of palletizing solutions running on Pally software, which currently powers more than 200 palletizing cobots globally.

Rocketfarm Digital Twin Simulations

The best method to reduce upfront risk

Feel free to reach out if you would like us to analyze your specific project or palletizing needs.

Brigt

Channel Executive at Rocketfarm

What we know and don’t know about palletizing with UR20

This was our detailed walk-through of what we know and what we don’t know about UR20 from a palletizing application point-of-view. Palletizing is more complex than it looks and so is the choice between UR10e and UR20 for those borderline cases.

The bottom line is that UR20 is well designed for palletizing and that a lot more companies will see cobot palletizing as a possible solution to their automations plans with UR20.

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.