A Cobot (collaborative robot) palletizer should add value to your business and production line. Is your cobot palletizer not working as it should? Doesn’t it deliver the value you expected, or is it simply not working?

If it doesn’t, let us help you.

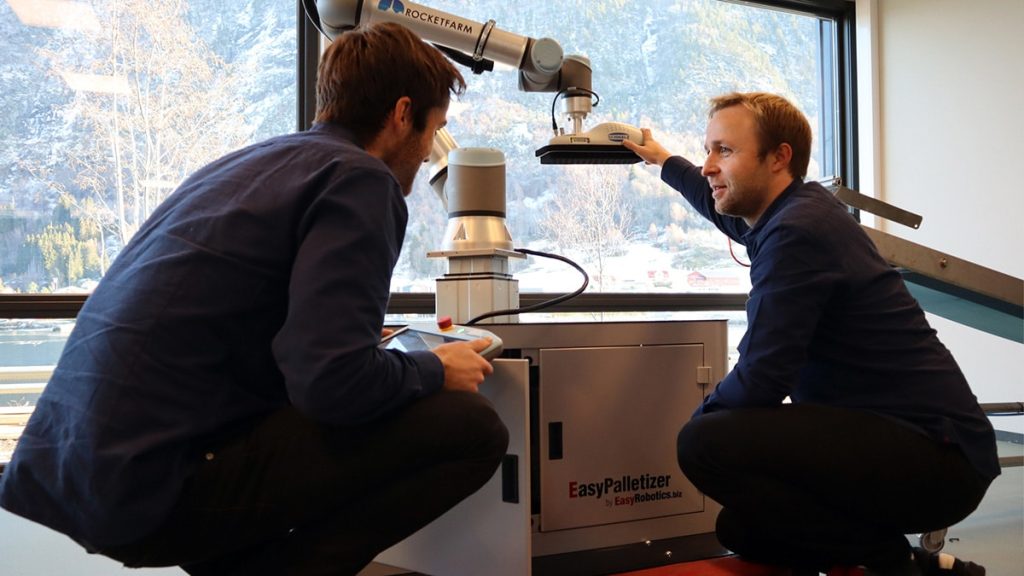

We have worked with Universal Robots and cobot palletizing since 2015 and have seen many issues through the years, and we know that we can help you get the value you expect from your cobot palletizer. Therefore, the following only applies to cobot palletizers from Universal Robots.

By implementing Pally software to your cobot Palletizer, we are very confident that we can help you solve the issues that limit the output from your cobot. Along with Pally, you will get access to our Robot Management Platform MyRobot.cloud, which allows you to store all your products, all your patterns, and your robot backup file, which you can use for digital twin simulations for verification and testing of new products and pattern on your actual robot.

Below we describe a few issues we hear about regularly with cobot palletizers and give you information about how Pally solves it).

Too much downtime when switching between products

If you have to stop the robot, re-calibrate, and re-program every time or even just sometimes when changing products, your cobot palletizer is not as efficient as it could be.

With Pally, switching between products/patterns without any downtime in production is possible. Choose the following pattern that’s needed and press start. You don’t need to stop the robot, you don’t need to re-calibrate, and you don’t need to re-program. With the Pally Operator Panel (user interface), your operators can do this with minimal training.

It’s as simple as described above, but one of the main reasons why adding Pally to your cobot palletizer will improve the ROI of your cobot palletizer. Downtime in production is usually very costly and should not happen.

Don’t know if your cobot palletizer can palletize new products/patterns?

Do you invest too much time and money trying to determine whether your cobot palletizer can palletize new products? Or do you avoid introducing new products to your cobot palletizer altogether?

With Pally and MyRobot.cloud, this is an issue of the past.

In MyRobot.cloud, you can validate and review performance with new products/patterns in 1 hour. This can be achieved without leaving your desk or impacting production.

Do it in 4 simple steps:

- Upload a backup file of the Pally installation onto a USB stick from the UR teach pendant.

- Upload the backup file to MyRobot.cloud as a robot configuration.

- Generate your new pattern and simulate it in MyRobot.cloud with the above-mentioned robot configuration.

- Receive the simulation report, showing whether the new product/pattern is compatible with an already existing installation.

See the example report from a review using a digital twin of cobot palletizing solution.

Not reaching high enough CPM

Are you not satisfied with the cases per minute (CPM) your cobot palletizer reaches, or has your production been updated, and you need your cobot palletizer to increase the CPM? But you don’t know how to achieve a higher output?

Pally offers you several options to improve CPM, both through the way it works and features that can be optimized for your needs.

Below is a walk-through of essential elements that allow Pally to palletize up to 30 cases per minute.

- Smart Pick is intelligent multipicking where the Pally algorithm chooses the number of boxes that is possible and most efficient to pick according to box dimensions, weight, and pattern (requires a gripper that can handle multipicking). See an example of smart-picking of boxes here

- Gripper optimization chooses the best direction to pick the boxes at the conveyor according to what’s most optimal for each specific box and each specific pattern

- Optimized path planning lets the Pally algorithm choose the best path from conveyor to box placement. Great for both reaching higher CPM and for robot longevity.

- Smart acceleration is a setting that combines grip quality and speed and chooses the best acceleration according to the settings selected. You can dramatically improve your CPM by choosing one of the faster options (medium is standard). Smart acceleration will affect how the robot will move with and without boxes.

Fun fact: This Pally-powered solution from Stimba palletizes up to 45 cases per minute

Not satisfied with your Return on Investment (ROI)

Our rule of thumb is that a complete palletizing solution usually has an ROI of less than one year. If that hasn’t been the case for you, you should consider if your cobot palletizer brings the value it should to your business.

It also depends on how many hours you expect your robot to be palletizing. But if you’re unsatisfied with the ROI delivered, it could be done more intelligently or better.

Automation should be a clear value-add to your business, not the opposite.

If you would like to discuss your cobot palletizer and ROI, you can contact us by email at pally@rocketfarm.no or by phone at +47 969 14 006 (08:00 – 16:00 CET). We’re confident that we can help you increase your ROI.

Learn more about ROI and cobot palletizing here.

Comparison between the UR Palletizing template and Pally

We have objectively compared the UR palletizing template and Pally for the entire palletizing automation journey, from the awareness stage in the beginning to the operational phase, where manufacturers take charge of the robot.

We have compared the differences you, as a manufacturer, will experience through your robotic automation journey. But we haven’t made any conclusions on what’s better or worse. That is for you to decide.

Read the comparison of the UR Palletizing template and Pally here.

Zero lost customers

It sounds too good to be true, but it is the truth. We have never experienced an unsatisfied customer with Pally.

On the contrary, we experience how customers ship their Pally cobot palletizers around the globe when their demand changes and the palletizer is of better use in other facilities. And we encounter, as with the Hawai-case, great satisfaction with customers who have tried cobot palletizing without Pally and then switches to Pally.

We’ll leave the last word to our very first customer:

The cobot palletizers are the robots we have with the highest operating time and lowest running costs.

Inghild Lysne Sanden

Factory Manager, Nortura Sogndal

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.