What does a robot cost?

Or more importantly:

What will you gain from investing in a palletizing robot?

As a rule of thumb: most businesses have a positive return on investment after the first year of use!

Below we have collected a few points that are good to keep in mind when calculating your ROI for a palletizing robot.

Training

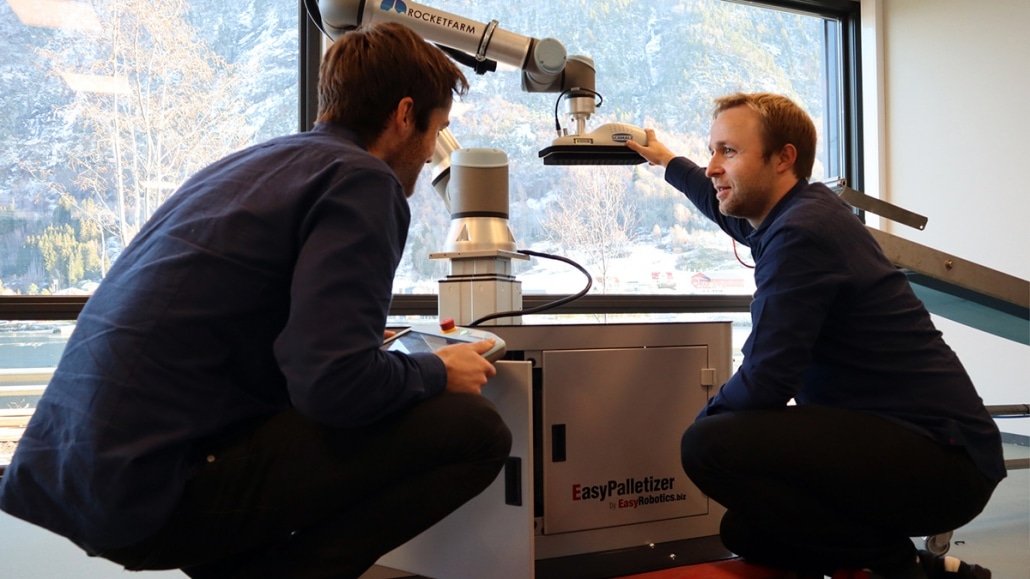

User-friendliness was important when we at Rocketfarm decided to develop a software for palletizing. With an interface that is easy to use, half a day of training with your employees will often be sufficient. An operator will then be able to make changes in the palletizing pattern, start and stop palletizing during normal operations, and make it continue from where it left off after an unexpected stop, such as emergency stop, power outage, etc.

Reorganizing the production area

A collaborative robot (robots that are working side by side with humans) from UR uses considerably less space than a traditional robot. A palletizing solution with a cobot seldom demands radical changes in the production area.

Downtime in production during installation

A stop in the production might be costly and demand a lot of planning. By choosing a palletizing solution with a cobot, the downtime can be reduced considerably versus other solutions, since both operators and integrators can work side by side at the end of the production line during the installation. Once installed the robot is ready to start palletizing immediately.

The lifespan of a robot

A robot is a machine with moving parts and over time these will tear depending on how it is used. Universal Robots promise 35 000 hours of use on their robots. By using the tailor-made UR software from Rocketfarm, Pally, the robot will move more smoothly, resulting in less tear on the different parts. This will prolong the lifespan of the robot and maximizes the value of your investment.

Less risk for strain injuries

A palletizing robot removes a strenuous work task for the employees. It could literally remove tons of lifting for a worker during his or her shift. As a result, the risk of strain injuries will decrease, and the worker can perform other, more valuable tasks. For many, this also means that they can stay longer in the job since the physical strain is minimized while job satisfaction is improved.

For Ægir Brewery, a palletizing solution from Rocketfarm meant that the employees could do other, more interesting tasks than moving boxes over to a pallet. Read the case story here

Find palletizing solution

Four things to think about when calculating the costs

1. Engineering costs

We divide expenses related to engineering into three main parts:

- Cost of installation: This varies from project to project, but both components and setup have been thoroughly tested to avoid any surprises. An experienced automation engineer will have your palletizing robot up and running after just one day!

- Risk assessment: Even if UR robots are certified to work side-by-side with humans, we will always perform a safety assessment according to applicable standards, certifications and regulations.

- Re-programming: This is a point that is easy to overlook, but it’s here you’ll really see the difference! By choosing our software Pally, you can quickly and easily change the pattern of your pallet yourself. You’ll save time and money by not having to hire an engineer on an hourly basis to re-program the robot.

In addition, Pally is giving you much greater flexibility and freedom in the palletizing opportunities than what comes standard with the robot.

You should consider using Pally in your robot if:

- You have more than one product per production line and/or often need to update this with new products,

- Your palletizing needs have rather complicated patterns,

- The finished pallet is over 120 cm tall,

- The palletizing speed demands that the robot lifts several boxes at once

Try our Fast Track to find available cobot palletizing solutions based on your region and product specifications. Within one hour you shall receive a digital twin simulation that can verify the feasibility of your palletizing cell.

2. Cost of parts

A palletizing robot consists of a few basic components: a robot, gripper, palletizing software, sensors and a base frame. The price for hardware will differ according to your needs and wishes, but in its simplest form, excluding the robot, you will find quality component kits for about EUR 10 000 – 12 000.

With our palletizing software Pally, you will be able to make your own patterns for free and change between them with no down time. With other providers this can cost thousands of Euros per pattern and result in significant production downtime.

3. Cost of operation

- It is recommended that UR robots undergo an annual maintenance service. This requires only a few working hours by a technician.

- The foam on a vacuum gripper will need some changing from time to time, but this is relatively inexpensive.

- Energy use: a UR-10 robot demands about 0,35 kW/h while it is running, so it is fairly energy efficient!

4. Future hiring costs

It is becoming increasingly difficult to recruit people to do repetitive tasks such as palletizing. This trend will most likely continue for the foreseeable future. By investing in a palletizing robot, you will minimize the need to hire for a task less and less people want to perform.

Seen together, these are factors that have an impact on what your

ROI could be by investing in a palletizing solution from us.

As a rule of thumb most businesses have a

revenue on the robot after the first year of use!

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.