The Top 5 Arguments For Managers To Invest In Automated Palletizing

Committing to new ways of doing things can be difficult.

As creatures of habit, we are comfortable with our established routines. Introducing something new and unknown when you are not certain of the outcome, can often be frightening. Getting production managers to invest in automated palletizing solutions is definitely one of these situations as it will fundamentally change current processes that everyone knows well.

It is understandable that production managers are skeptical of changing a process that already exists for the promise of doing it in a more efficient way.

Why should you change something that already works? It is a relevant question. However, employees on the ground also need to ask questions. The two most important things for them to ponder are; Why do we do it like this, and could this process be improved?

Often, there is a more efficient way of doing it. Especially today when new automated solutions to all kinds of manufacturing challenges are rapidly emerging. If your manufacturing processes involve a lot of manual labor, there is a high probability that there is a more efficient way of doing it. Often, this is found through automation.

5 arguments for investing in automated palletizing

The last few years have seen a breakthrough in automated palletizing technology. New solutions are in development which will shake up the manufacturing industry. By the end of this article you will have more knowledge of these breakthroughs as well as the following 5 reasons for your production manager to invest in this revolutionary technology:

- Return on investment (ROI)

- A solution for everyone

- The impact on employees and the organisation

- The product quality and cost effectiveness

- The optimization of the production process

1. Return On Investment (ROI)

When talking about the automation of processes within a business, we are ultimately seeking more efficiency, reliability and quality. This goes hand in hand with ROI. Long term use of automation solutions will be more efficient, reliable and provide more quality than a manual process.

However, when we think about ROI, it is important we take into consideration the following seven variables: the previous workforce costs, the costs of the specific palletizing solution, the installation setup, the production rate, the product, market trends and marketing efforts. We are confident that if palletizing solutions are utilized, there will be a positive ROI at some point and normally in a shorter timescale than you would imagine.

ROI for automated palletizing solutions

Cobot palletizing solutions usually have a positive ROI within 1 year.

This is due to the efficiency, reliability, and the product quality that the palletizing solutions provide. As a consequence, we can expect increased productivity and consistency within the manufacturing process.

Learn more about how to calculate ROI for a palletizing solution here

2. Many available solutions in automated palletizing

An outdated assumption about automated palletizing is that it is not an adaptable solution as your business grows and that it is a large initial investment. Today, there are many palletizing solutions available to match your particular needs. This is true both if you are a small-scale manufacturing facility or have a larger factory with a high production rate.

Read more: Getting SME automation right – which cobot is right for your business.

Difference between industrial and cobot palletizing

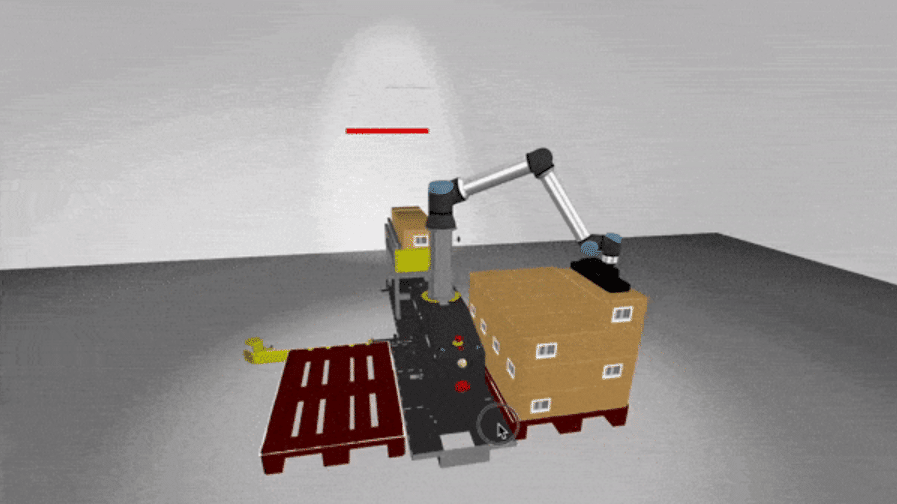

A common differentiation between palletizing solutions is whether they are industrial or cobot powered. Industrial palletizing solutions are large and complex systems with a high case-per-minute (CPM) throughput of low mix products. These solutions are ideal for large manufacturing facilities with a high production rate.

On the other hand, cobot powered palletizing solutions are small in their footprint. These cobots will handle a lower CPM, but with an agile possibility of tending a high mix of products. Another important aspect of using cobot palletizing solutions, is that it can also allow humans to work in close proximity to the operating robot.

The bottom-line is that there is an automated palletizing solution out there for any manufacturer. It’s about finding the right one to fit your needs.

3. Positive impact on employees and the organisation

The most important resource in any organisation is its employees. Keeping them happy should be a top priority. Do any employees like to do strenuous and repetitive tasks all day? Let’s be honest – no. This kind of work can negatively affect both mental and physical health. In the worst case scenario, this can have an affect on the health of the organisation as a whole and ultimately impact its performance.

“I hired a robot for the same reason I’ve made lots of choices in the business. I don’t want to wear my people out. At our facility, everyone would take part in palletizing from time to time. It was not a popular job. Or to be honest, they hated it.”

Evan Lewis

CEO, Ægir Brewery

Learn more: How a palletizing solution made the employees happy at Ægir Brewery

Positive outcomes with automated palletizing solutions

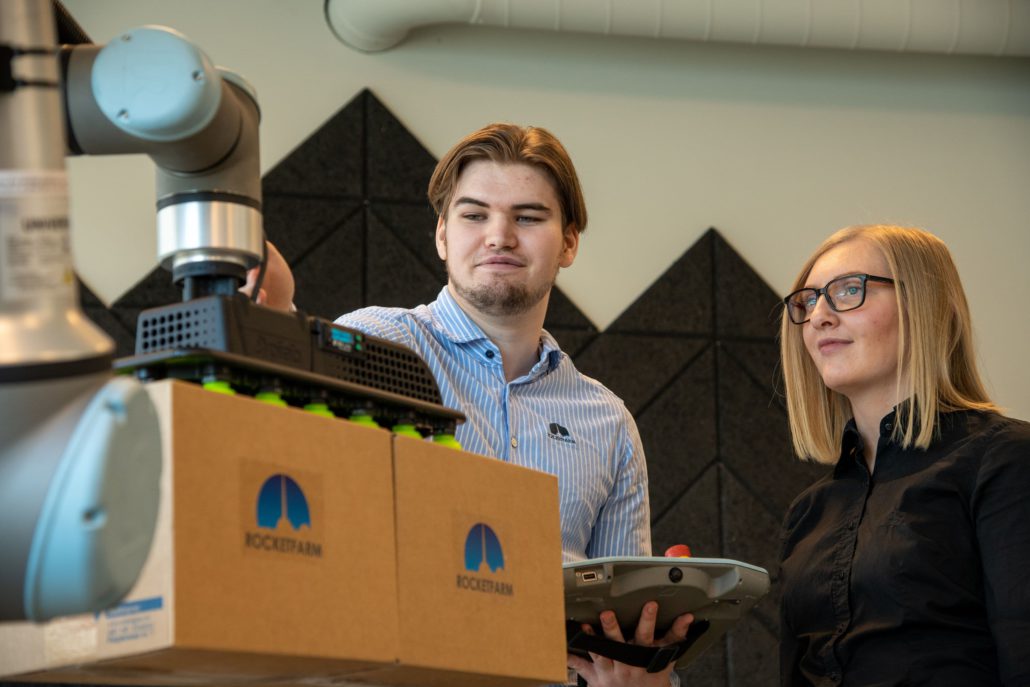

There are also other positive outcomes for employees and the business by adopting an automated palletizing solution. For starters, you are freeing the employees from their previous tasks, enabling them to focus on other, more important ones that do require human tending. There will also be less time focussed on finding and training up labour substitutes and more time for actual manufacturing.

Automated palletizing – A recruitment tool

Having a robotic palletizing solution can also become a great recruitment tool. This can inspire happiness and show newcomers that the organisation is prioritizing the work environment by actively investing in and utilizing modern automation.

Click here to learn more about why palletizing automation will make employees happy

An important note to keep in mind is that even though these benefits are difficult to quantify, they can often add up together to significantly shorten the timescale for your business to get to a positive ROI on your palletizing solution.

4. Increase product quality and cost effectiveness

The quality of the product you deliver is the major determinant of how you are perceived as a business. If humans are working on a production line, they can contribute to variation in this quality. Occasional mistakes are bound to happen. This is only natural, but as a business you want to limit this as much as possible in your production line.

Less variation in product quality

Automated palletizing solutions will seldom make mistakes on the production line. . They are programmed to carry out the same perfect repetitive movements over and over again. This eliminates occasional and unnecessary return of damaged products, as well as waste of time and resources.

“The flexible cobots make no mistakes, unless they are programmed for mistakes, they smile. One of our cobots has been working around the clock for two years, with no exceptions. If we had had our employees do the same job manually, salary and social costs would have quickly been close to 200k USD per year.”

Knut Thomassen

Head of Production, Maskinpakking AS

In terms of its cost effectiveness, you can expect benefits in their long term use, as these systems do not take a break (unless you want it to). They will help decrease downtime and potential bottlenecks in the manufacturing process, while maintaining productivity and consistency in its results.

5. A great addition to optimizing the manufacturing process

No matter the size of the organisation, it is important to think of palletizing automation as a part of a continuous journey of improvement.

Without an automated palletizing solution, the whole production line would be dependent on employees stacking cases. If there are changes to the availability of the workforce or to the demand for the product – this will affect how many products that can or need to be stacked. As a consequence, this means you can have both stressful work days with few staff or work days where your production line is over staffed.

In contrast, automated palletizing solutions are ready at any given moment and can easily adapt to the demand for your product

Read more: Palletizing with Cobots – Everything you need to know

Ask questions

It is important to ask questions about why we do the things we do. That is how we continue to improve. By asking questions we can identify potential problems, solutions and make a plan on how to reach a predetermined goal. A process, or if repeated over and over again, a continuous journey of improvement.

As a part of this improvement, an important piece of the puzzle is the employees. By recognizing problems and even potential solutions, they can supply managers with valuable insights and information.

Get started today

In this article we have mentioned five arguments for production managers to invest in automated palletizing. Solutions do exist for most manufacturing companies that need to stack finished products on pallets.

To really get started today, talk to your production manager about automated palletizing. Because maybe you know something that the manager does not know. Knowledge that is worth sharing to create a better version of your company.

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.