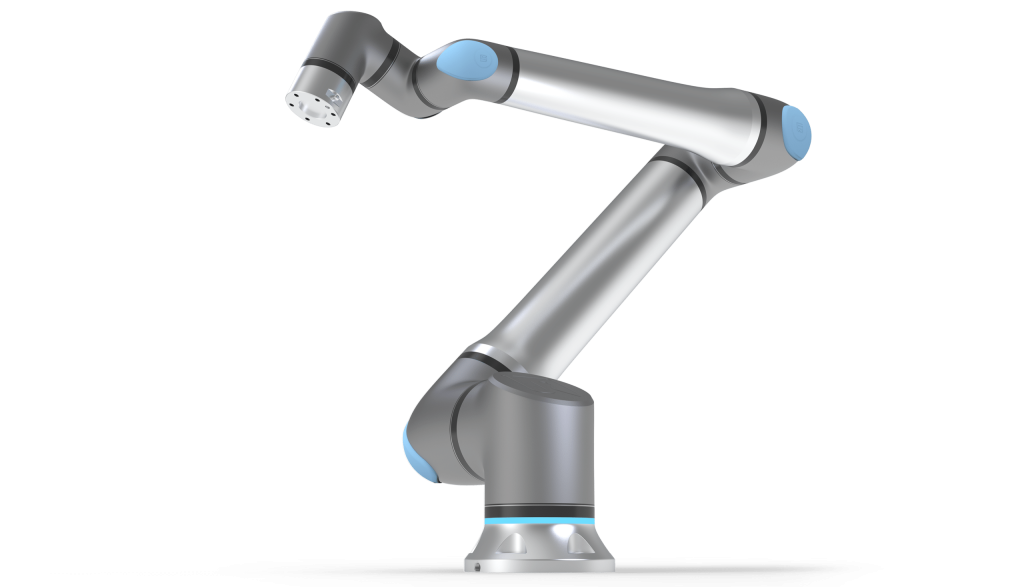

This is the cobot – redefined! It’s a next-level collaborative robot designed to make automation more accessible for small and medium-sized enterprises worldwide. Undoubtedly, UR must have considered palletizing when creating the UR20.

In this article, we’ll explore all the facts, features, and benefits of the UR20 cobot. Learn everything you need to know about Universal Robots’ largest collaborative robot.

Introduction to UR20

Universal Robots‘ UR20 is designed to improve performance. It is their first cobot, which they call the next generation of industrial cobots. It brings a new level of performance and embraces key concepts for Universal Robots, such as versatility, small footprints, and usability.

UR20 Tech Specifications

- 25 kg / 55.12 lbs payload (the added 5 kilos is available with PolyScope 5.19)

- With up to 15 cm offset in full range of motion

- The robot weighs 64 kg / 141.1 lbs

- The lightest cobot with this payload on the market

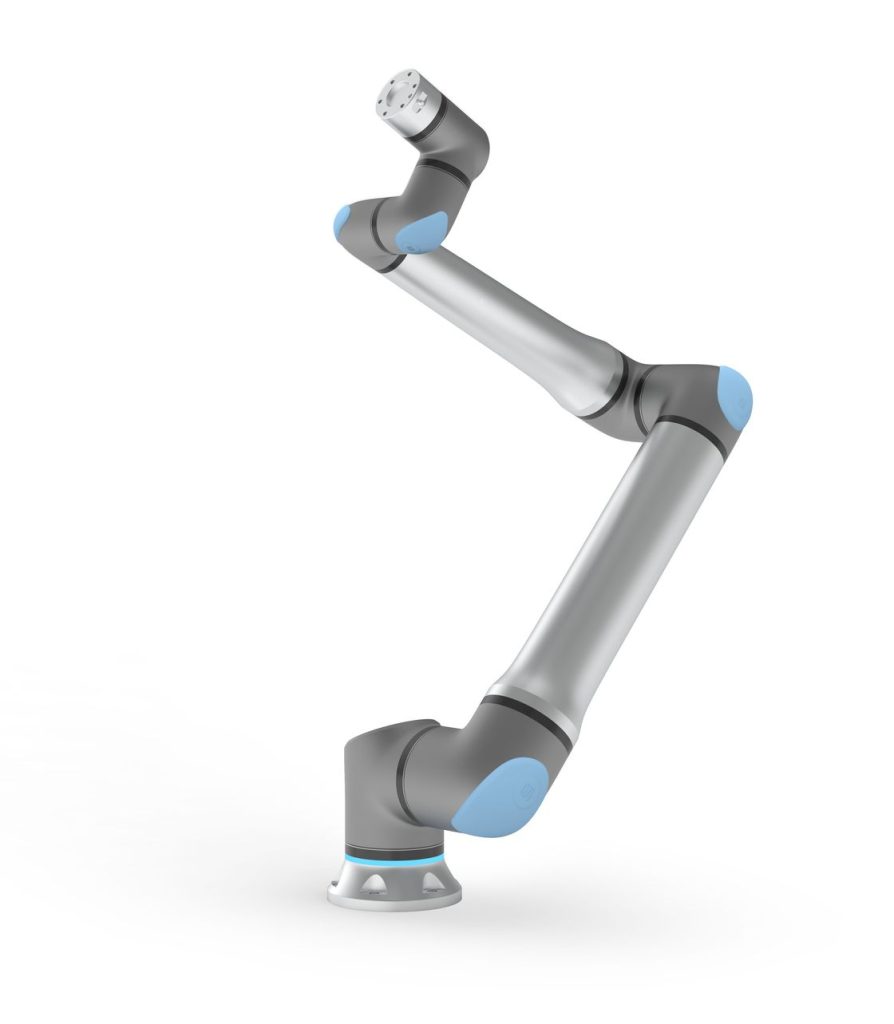

- 1750 mm / 68.9 in reach

- Palletize up to 2 m euro pallet with no lifting column

- The software will be completely updateable

- ⌀ 245 mm footprint

- 65% more speed

- 25% more torque within a closed capsule

- 700 newton in the largest joints

- Can be mounted on any surface (floor, wall, ceiling)

- LED indicator for at-glance alerts

- Improved and different speed in every single joint (keeps strain of the robot low)

- Product development feedback from more than 250 UR+ approved partners

- Existing URCaps will continue to be supported by UR20

- All safety certifications for current UR robots will continue (one new added for the US market)

Download the complete Tech Specification sheet via Universal Robots

The benefits with the UR20 robot

| Features | Benefits |

| 25 kg payload | A 25 kg payload in full reach, with a 15 cm offset, gives you a whole new range of possibilities. |

| The robot weighs 64 kg | At 64 kg, it’s the lightest cobot with this payload, which makes installation easier and allows you to think differently about the installation as it can be mounted on any surface, on the floor, wall, or ceiling. Really opening up a lot of new possibilities for space management and using the cobot in smaller facilities. |

| 1750 mm reach | The extended reach opens up new possible application areas without requiring investment in other hardware. For palletizing applications, it minimizes the need for a lifting column, which improves the time required to stack a full pattern. It will be able to palletize up to 2m euro pallets with no lifting column. |

| 245 mm footprint | Very small footprint, like a dinner plate. Allows you to install the robot even with limited floor space. More flexible and with more possibilities for customization, making it work effectively in a manufacturing space. |

| Updateable software | Every part of the UR20 software can be updated and will be continuously updated. |

Making Palletizing Available

From our perspective, and as highlighted by Universal Robots, the UR20 cobot is ideally suited for palletizing. It features a higher payload at the full range of motion and a bigger reach. Both will benefit customers looking for a palletizing solution.

Read our in-depth analysis of the UR20 for palletizing

The UR20 makes cobot palletizing accessible to a wider range of manufacturers due to its higher payload and extended reach. We’ve seen a high demand for palletizing solutions in this payload range.

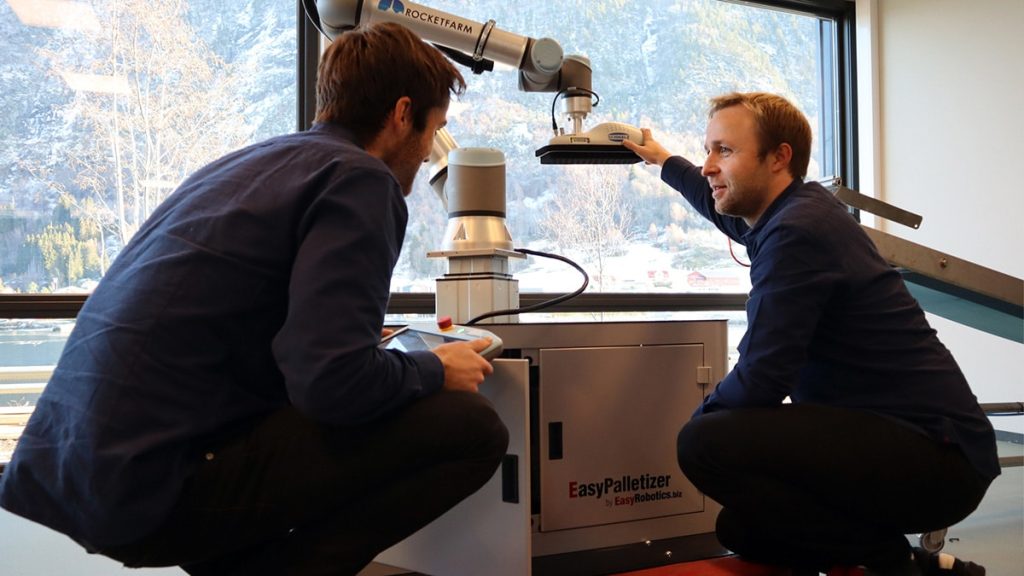

Egil Mundal

Chief Executive Officer at Rocketfarm AS

Pros and cons

The payload up to 25kg, long reach, and faster movements really make the UR20 well-suited for palletizing. Below, you’ll learn about the pros and cons.

Pros:

- Lift heavier boxes

- More boxes per minute (a higher cycle time)

- Increased safety (by picking more boxes per lift and slowing the robot down)

- It will also reduce wear and tear and improve the longevity of the robot

- Reduce the need for lifting the column

Cons:

- More safety requirements if run at higher speeds (fencing, sensors, etc.), which will increase the solution price

Heavier Boxes

The ability to palletize heavier boxes is self-explanatory. With the UR20 cobot’s higher payload, it will be able to lift heavier boxes. On the UR10e (the currently most used UR cobot for palletizing), you can palletize up to 12.5 kg. On the UR20, the maximum weight is 25 kg.

Higher Cycle Time

The UR20 robot is 60% faster than its predecessors (or competitors), which will enable the robot to complete more cycles per minute simply by moving faster.

However, it can also increase cycle times for projects with lower box weights (below 10 kg), as the higher payload allows the UR20 robot to utilize multipicking of boxes, which increases the number of boxes to be palletized within a given time period.

Slower Robots

Another benefit of being able to multipick boxes is the ability to run the robot at a slower speed. Just because the robot is faster, it might not be necessary for your application to run the robot at full speed. By running the robot as slow as possible to meet demands, the solution will be safer, the strain on the robot will be lower, and you will have bandwidth for future production improvements.

The goal is to run the robot as slowly as possible while still meeting production demands. This increases the safety of the solution and the longevity of the robot, hence improving the lifetime value of the robot. By multipicking boxes, you can drastically decrease the speed.

Halvor Gregusson

Chief Innovation Officer at Rocketfarm AS

Keep reading or download our free UR20 Ebook to learn more

Less Hardware

With its longer reach and ability to palletize up to 2m euro pallets without a lifting column, a UR20 palletizing solution requires less additional hardware. This has several advantages, as fewer hardware components mean fewer parts that can break and fewer parts that require spare parts. Overall, this will equal a more robust palletizing solution.

Less hardware also presents its challenges in terms of robot reach. Learn more in our in-depth analysis of palletizing with the UR20.

There were a number of applications that our portfolio didn’t cover [before the UR20], but specifically packaging and palletizing. Moving 40-lb boxes onto a pallet over and over again, day after day, is a task that you should not be doing. We had lots of conversations with customers about how we can help them deal with these challenges.

Kim Povlsen

CEO, Universal Robots. From The Robot Report

What’s in the Box?

A standard UR20 will include the following:

- A 25 kg payload arm

- Control box

- 3PE Teach Pendant (with an integrated 3-position enabling device)

- Power cable

- Cable between the manipulator and the control box

- Documentation

See all frequently asked questions (FAQ) about UR20 by downloading this FAQ sheet

UR20 and Pally

The UR20 is, of course, compatible with Pally!

Pally is the leading palletizing software for Universal Robots, designed to make cobots from Universal Robots easy to operate, easy to install, and compatible with most hardware on the market. Pally guarantees you receive the optimal palletizing solution.

How to Get the Palletizing Solution You Need? Choose a Pally Palletizing Solution

Combining Pally and UR20 equals an enormous potential, as many of Pally’s benefits become even more significant with a larger cobot. The ability to smart-grip boxes (based on calculations, Pally determines how many or how few boxes to pick) enhances safety, increases cycle time, and reduces strain on the robot. With an increased payload, the possibilities are vastly improved.

Improved Lifetime Value

Pally enhances path planning and ensures smoother movements, which will be increasingly important as the robot has the potential to move and accelerate faster. By selecting a more optimized path and achieving smoother movements, the robot’s lifespan will improve, and thus the lifetime value (LTV) in a solution with Pally will outperform that in a solution without Pally.

Reach out if you would like to learn more about how Pally can help you achieve your goals in automated palletizing.

Brigt Grepstad Røysum

Sales Lead at Rocketfarm AS

Subscribe to our newsletter

To be the first to know when Pally and Digital Twin Simulations are ready for UR20