Reduce adoption time and increase the quality of decision making

Rocketfarm has made significant efforts to create a technology adoption tool. Digital Twins is a unique technology that enables cobot palletizing solutions, providing prompt verification and performance reports. We’re proud to share that one of our previous colleagues, Mathias Flo, based his Master’s Thesis on this innovation.

The focus of the thesis study was to determine the extent to which a Digital Twin Simulation provides value in decision-making for the adoption of cobots in palletizing tasks.

Mathias Flo received positive feedback for his work, and his Master’s Thesis presents some interesting findings.

This article offers a summary of his research.

Expediting Technology Adoption Through Simulation

Through interviews, presentations of simulations, and feedback, the thesis shed light on how digital twin technology can contribute to raising knowledge in the decision-making process for the adoption of cobots.

To answer the thesis statement, “How can technology adoption be accelerated using a digital twin simulation tool?” Flo used the collaboration between Rocketfarm and Nortura as his case study.

Nortura is one of Norway’s biggest food producers and a cooperative owned by over 17,100 farmers. They are currently in the middle of a transformation towards Industry 4.0 and are highly relevant for this subject.

Read more: This is how the digital twin simulations from Rocketfam helped Nortura perform 30% better

Wanted to increase knowledge

Flo’s thesis aimed to increase knowledge about how digital twin- and simulation technology can influence the decision-making process associated with adopting Industry 4.0 technology. This was done in an Industry 4.0 context, where the empirical foundation was the coherence between businesses’ ability to adapt and compatibility.

Through Industry 4.0 and its implications, companies have reached a point where they must choose an approach to the constant technological advances. What they decide will shape the competitive situation of the individual company.

Contribution of Digital Twin Simulation

To highlight which opportunities and barriers influenced the intention of technology adoption, the thesis examined what made adoption decisions time-consuming.

Automation of processes is primarily done to increase productivity and solve tasks that are not suitable for humans.

”In the study, the digital twin technology was found to be a valuable tool in the decision-making process for cobot solutions. With the technology, manufacturers can find the palletizing solution for their exact needs. With this tool, the process is less costly and time-consuming, while still being as reliable as it needs to be.”

Mathias Flo

Account Executive

However, the thesis found other factors that affect the intention to adopt new technology. The thesis explores these factors and how digital twins can contribute to decision-making. The study highlights that they positively impact three key aspects: investment, uncertainty surrounding the technology, and compatibility of the cobot technology.

Key findings

The master thesis concluded with five main findings that were key to answering the question of how digital twin simulation can increase the speed of automation in a manufacturing company.

These are Flo’s findings:

1. Investment

The first main finding deals with infrastructure. When adopting technology is considered, it is often up against the value of keeping current machines. This is part of the justification of the investment and is thus a natural part of the decision-making process.

At the same time, replacing existing machines in the equipment package can be challenging, as these are also investments made to serve the business for a longer perspective. However, it is necessary to renew the infrastructure in line with technological development. This is a criterium for taking advantage of the opportunities Industry 4.0 brings.

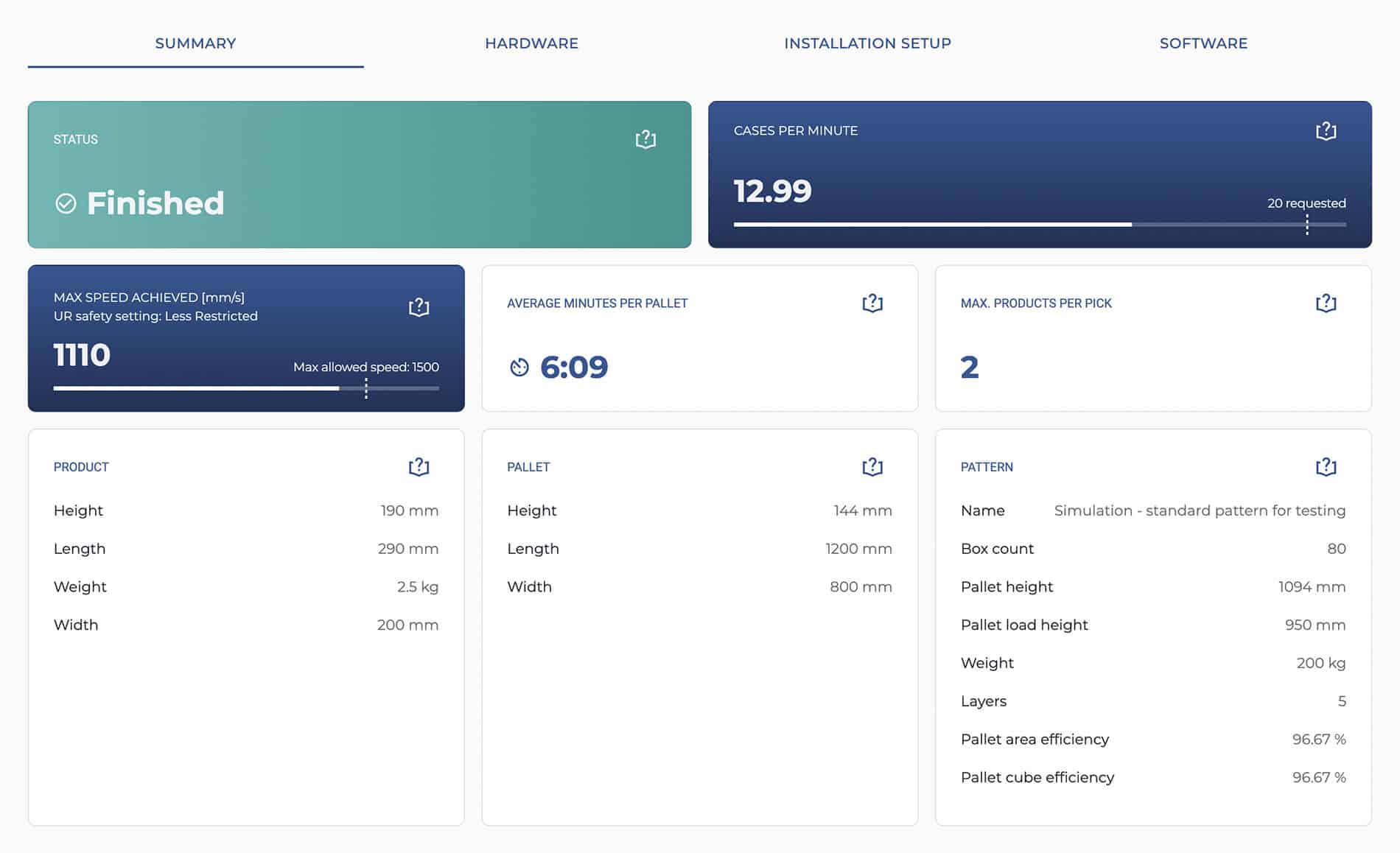

The thesis found the output data from a digital twin simulation valuable for the decision-making process. With this data, a decision maker can conduct a benefit-cost analysis of the investment. This data output helps the decision-maker make a more knowledge-based decision.

2. Shorter installation time

The second finding identifies how digital twin technology shortens the installation time of a cobot palletizing solution. The palletizing pattern is already created, tested, and validated through the technology.

In the case study, the informant from Nortura pointed out how the digital twin technology significantly removed or reduced the installation time of cobots – the shorter installation time had a significant impact on the decision to invest in cobots and faster installation time results in less need for production downtime. The price of the investment will be significantly affected by this.

Here you can build your palletizing pattern and have it tested and validated

3. Reliability

The third main finding is related to the reliability of the technology.

For technology to serve its intended usefulness, it must be reliable. Within this, it is added that the simulation tool is a precise and credible representation of what it represents – in this case, cobots.

The same applies to the decision-makers opinion regarding having cobots do palletizing tasks. If the cobot is not associated with operational reliability, it will probably not be bought.

The Digital Twin Simulation made the decision-maker more reliable in adopting the technology, and the simulation tool was perceived to be precise and credible.

4. See the solution before buying

The fourth finding concerns the visualization of the cobot’s footprint.

Saving space is a key factor in adoption decisions. An impression of the cobot’s actual size is made through visualization of the palletizing. This is a factor that can potentially influence the adoption decision.

It is beneficial to have the footprint quantified in the performance report. This will further enhance decision-making knowledge.

This is how your performance report from Rocketfarm would look like

5. Further development of the technology

The fifth and final main finding concerns the adaptability of cobot technology.

The ability to adapt refers to the time it takes to readjust the cobot when the product changes at the production line. This is additional information that does not emerge through the simulation. However, it is emphasized in connection with adaptation decisions.

Automating the product changes will be an autonomous process. It would not require human intervention. It would be advantageous to justify the investment financially by showing resource savings.

Summary

To stay competitive, businesses must embrace technological advancements. The study shed light on how digital twin technology can contribute to the decision-making process related adoption of cobots. The study shows that digital twin simulations can enhance decision-making when incorporating cobots into operations.

The examination shows how the simulation tool reduces uncertainty through visualization and data output. At the same time, the verification aspect plays a central role in testing the feasibility and identifying the areas where cobots can be used. The Digital Twin Simulations also shorten the installation time and clarify other key cobot characteristics.

As a result, the simulation tool is assessed as a helpful supplement in Nortura’s decision-making process. There are reasons to believe this applies to other companies or market segments.

Conclusion

Based on the findings, it is evident that digital twin technology benefits its users. It facilitates knowledge-based decision-making and significantly reduces adoption time when integrating new technology.

With more information at your disposal, it is much easier to make informed choices. It is, therefore, fair to say that Digital Twin Simulations reduce the perceived risk for both the company and decision-makers and speed up the automation process.

In conclusion, digital twin simulations are a valuable asset that will reduce some of the investment risks.

Eager to test it for yourself?

Try the simulation tool here – for free!

Sign up for our newsletter and get a FREE ebook

By signing up for our monthly newsletter, you’ll get case stories, product launches, and tips to automate your production line!

Additionally, you will instantly receive an ebook about implementing palletizing. For more information, please visit our newsletter subscription page.